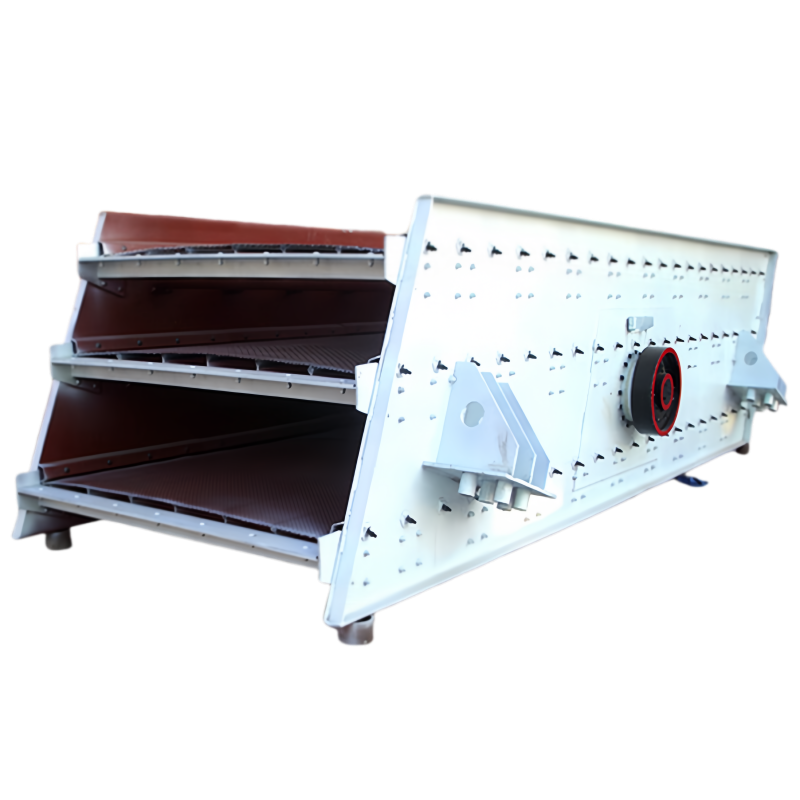

Circular Vibrating Screen

Maximum screen area: 48㎡

Maximum sieve hole size: 5-120mm

Maximum feed size: 200mm

Maximum processing capacity: 150-800m³/h

Vibration power: 970r/min

Maximum motor power: 6p-45kw

Maximum screen size: 3000*8000mm

- Single large processing capacity, significant cost reduction:The maximum output of YK series linear screen can reach 800-1000 tons, greatly reducing the number of vibrating screens and belts in the production line, reducing the input cost by 45% and reducing the maintenance cost by 30%.

- External eccentric block with adjustable amplitude:The exciter adopts external eccentric structure, compared with the shaft eccentric vibrator, the exciting force is enhanced, the weight is reduced, and the maintenance and replacement are convenient. By increasing or decreasing the number of counterweight blocks to adjust the exciting force, to meet the requirements of different specifications of vibrating screen processing capacity. The exciter is connected by universal joint coupling, flexible installation and replacement, and long service life.

- Rubber composite spring support, smooth operation:The vibrating screen adopts rubber composite spring vibration damping support, which has the advantages of long life, fast over-resonance area, stable operation, low noise and small impact on the foundation.

- No solder joint connection, avoid deformation:The side plate of the screen and the beam are connected with high strength ring groove rivets to eliminate welding stress, run more smoothly, the screen body has reasonable force, and effectively avoid distortion caused by uneven force.

- Brand parts, stable performance and long life:YK series vibrating screen selection of domestic high quality brand bearings, domestic high quality brand drive shaft, with high quality high manganese steel woven screen, parts of high quality, long service life.

- Simple structure, convenient maintenance, diverse discharge:Screen machine structure is simple, layer space is large, screen replacement is convenient. Multiple layers of screens with different apertures can be installed as required to screen out a variety of specifications of finished materials.

EQUIPMENT

The company mainly produces a complete set of equipment for coarse and fine crushing production lines of various hard materials such as coal gangue (solid waste) and mines, with high-fine crushers as the leading products.

SUPPORT

ZDMACHINERY's after-sales sales/service team is proud to provide 24/7/weekend service to support any emergency

RESOURCES

ZDMACHINERY's primary goal is to find just theright solution to help your businessgrow and stay profitable.

CONTACT

Contact us now to find out how wecan support all of your crushing,screening and conveying needs.