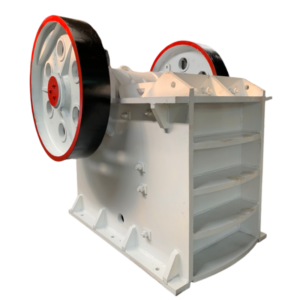

Jaw Crusher

Maximum feed opening size:1200*1500mm

Maximum feed size:1020mm

Maximum discharge opening size:150-300mm

Maximum processing capacity:400-800T/H

Maximum motor power:200-8(kw)

Maximum weight:100.9t

Maximum overall dimensions:6380×5310×3710mm

- Unique structure, enabling high yield and high efficiency:

1. Innovative crushing chamber: Carefully create a deeper symmetrical “V” shaped crushing chamber, which is precisely consistent with the nominal entrance width. The crushing ratio is greatly increased, the feeding capacity is enhanced, the output is jumped, the product particle size is fine, and the production needs are met, which lays the foundation for the subsequent process.

2. Strengthened bearing seat: The whole cast steel bearing seat fits seamlessly with the crushing frame, with high precision. Greatly enhance the radial strength, give the equipment high load operation of excellent stability, ensure continuous and efficient operation.

3. Flexible adjustment device: gasket type outlet adjustment device, wide adjustment range, whether coarse or fine-grained needs, can easily meet the individual requirements of different production scenarios. - Advanced technology ensures smooth operation:

1. Precise adjustment parts: flywheel, groove wheel and counterweight block are reviewed and adjusted with strict parameters, and operate harmoniously. Effectively reduce the overall vibration of the equipment, significantly improve the running stability, reduce component loss and failure risk, and ensure long-term high-intensity operation stability.

2. Efficient drive system: direct motor drive, simplify transmission, greatly reduce energy consumption, more stable and efficient operation. Not only improve the efficiency of power transmission, but also reduce the hidden trouble of intermediate transmission and enhance the reliability of operation.

3. Balanced inertia flywheel: The well-designed flywheel has excellent inertial balancing characteristics and plays a key buffer role in the operation of the equipment. Offset the impact force of the crushing moment, maintain the stable operation of the equipment, and ensure the continuity of production.

4. High load bearing: equipped with large size bearings, significantly improve the load capacity. Excellent performance in the face of huge radial and axial loads, ensuring stable operation of the equipment and extending the overall service life. - Highly automatic, energy saving and low noise:

1. Intelligent operation protection: the motor has excellent function, can be started and stopped with load, and can also run stably under full load or overload extreme conditions. High degree of automation reduces manual intervention, improves production efficiency, and advanced overload protection mechanism ensures equipment safety.

2. Energy saving and noise reduction parts: using high-quality cast steel jaw assembly, movable jaw assembly and flywheel, forging billet processing heavy eccentric shaft. Ensure efficient crushing, significantly reduce energy consumption and noise, single energy saving 15%-30%, system energy saving more than double, to create a comfortable environment for operators. - Selected raw materials, cast durable:

1. High manganese steel guard plate: high manganese steel toothed guard plate increases the effective length of the jaw plate and improves the output rate of the finished product. Optimize heat treatment process, both pressure and wear resistance and high flexibility, extend service life and reduce maintenance costs.

2. Cast iron elbow plate: carefully designed cast iron elbow plate, high insurance factor. When unbreakable objects enter, critical components are protected from accidental impact damage.

3. Solid welding frame: The welding frame is stress-relieved to eliminate internal stress and make the structure more durable. Enhance overall strength and improve reliability and stability under complex operating conditions.

4. Durable jaw: Advanced jaw components, high-quality materials, exquisite workmanship, high durability. In frequent crushing operations, effective resistance to wear and impact, prolong the service life of the equipment. - Strong impact resistance to ensure stable operation:

1. Split cast steel frame: split welded cast steel frame, simple design, excellent impact resistance. It can effectively disperse the impact force of material crushing, ensure the stability of the frame, and lay the foundation for long-term stable operation.

2. Heavy component combination: The optimized combination of heavy eccentric shaft and large size bearing provides strong impact resistance support for the moving jaw assembly. In high frequency and high strength crushing, it can withstand the impact force, ensure the stable operation of the moving jaw, and prevent equipment damage and performance decline.

3. Heavy protection plate: The heavy protection plate is installed above the moving jaw to withstand the strong impact of falling materials. Protect the moving jaw parts, extend the service life, and ensure the stable operation of the equipment when handling large particle size and high hardness materials. - Convenient operation and maintenance, improve user experience:

1. Convenient adjustment lubrication: The gasket type discharge adjustment device operates intuitively and can adjust the discharge particle size quickly and accurately. Centralized lubrication system realizes automatic lubrication of key components, simplifies maintenance process, reduces maintenance workload, and improves operation efficiency.

2. Symmetrical jaw plate design: the jaw plate adopts a symmetrical structure, which can be adjusted up and down after wear, extending the service cycle, saving replacement costs, reducing equipment downtime, and improving production efficiency. - Environmental protection and efficiency, practice green concept:

1. Low noise operation design: design and manufacture strictly according to environmental protection standards, optimize structure, select high-quality parts, effectively reduce working noise, reduce noise pollution to the surrounding environment, and create a quiet and comfortable environment for personnel.

2. Supporting dust removal and environmental protection: Professional dust removal equipment can be flexibly equipped to effectively collect dust in material crushing and conveying, reduce dust flying, reduce air pollution, meet environmental protection requirements, protect the health of operators, and achieve harmony between production and environmental protection.

EQUIPMENT

The company mainly produces a complete set of equipment for coarse and fine crushing production lines of various hard materials such as coal gangue (solid waste) and mines, with high-fine crushers as the leading products.

SUPPORT

ZDMACHINERY's after-sales sales/service team is proud to provide 24/7/weekend service to support any emergency

RESOURCES

ZDMACHINERY's primary goal is to find just theright solution to help your businessgrow and stay profitable.

CONTACT

Contact us now to find out how wecan support all of your crushing,screening and conveying needs.