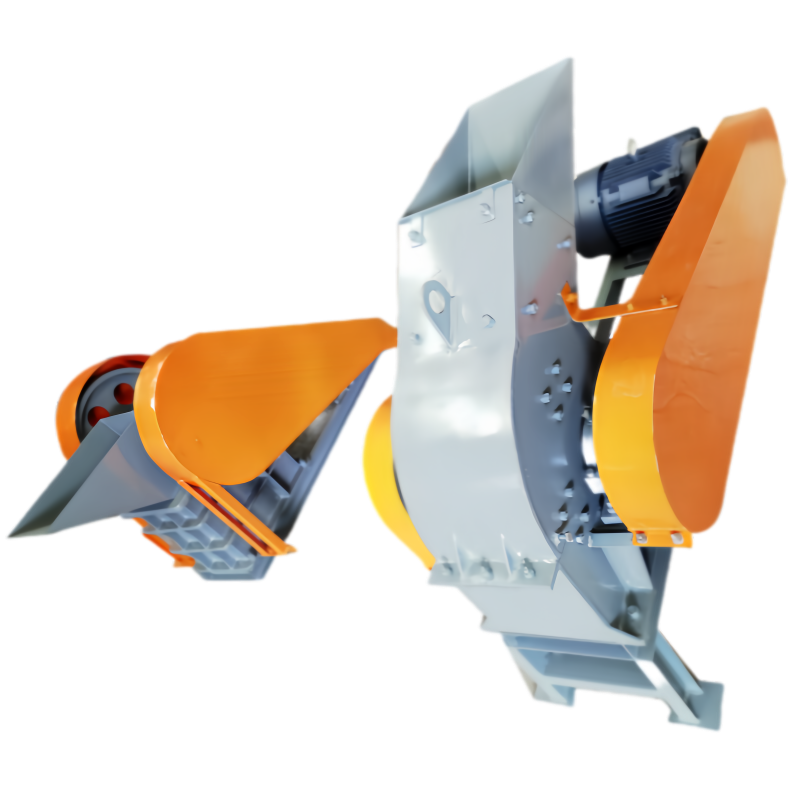

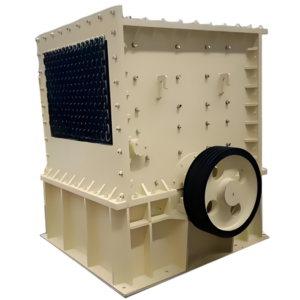

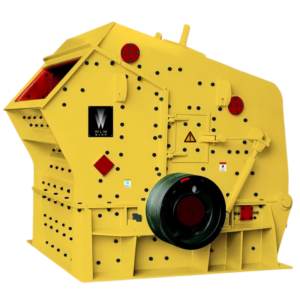

Hammer Crusher

Feeding size: ≤350mm

Discharge particle size: ≤35mm

Maximum production capacity: 30-55m³/h

Maximum motor power: 90kw

Total weight: ≤8t

The hammer crusher mainly relies on the impact energy to complete the crushing material operation. When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, the material evenly enters the crusher chamber, the high-speed rotary hammer impact, shear tear the material causing the material to be broken, at the same time, the gravity of the material itself makes the material rush from the high-speed rotating hammer head to the baffle in the frame, the screen bar, the material larger than the size of the sieve to remain on the sieve plate continue to be hit and ground by the hammer. Until broken to the required discharge particle size and finally through the sieve plate out of the machine.

- Working hammer, casting by new process, with wear resistance and impact resistance.

- According to customer requirements, adjust the required granularity.

- The hammer breaks the structural seal of the body, which solves the problem of dust pollution and ash leakage of the body in the crushing workshop.

- The overall design is beautiful, compact structure, less wearing parts, easy maintenance and other advantages, is to upgrade products.

- Compact structure, beautiful appearance, good wear resistance, easy maintenance.

EQUIPMENT

The company mainly produces a complete set of equipment for coarse and fine crushing production lines of various hard materials such as coal gangue (solid waste) and mines, with high-fine crushers as the leading products.

SUPPORT

ZDMACHINERY's after-sales sales/service team is proud to provide 24/7/weekend service to support any emergency

RESOURCES

ZDMACHINERY's primary goal is to find just theright solution to help your businessgrow and stay profitable.

CONTACT

Contact us now to find out how wecan support all of your crushing,screening and conveying needs.