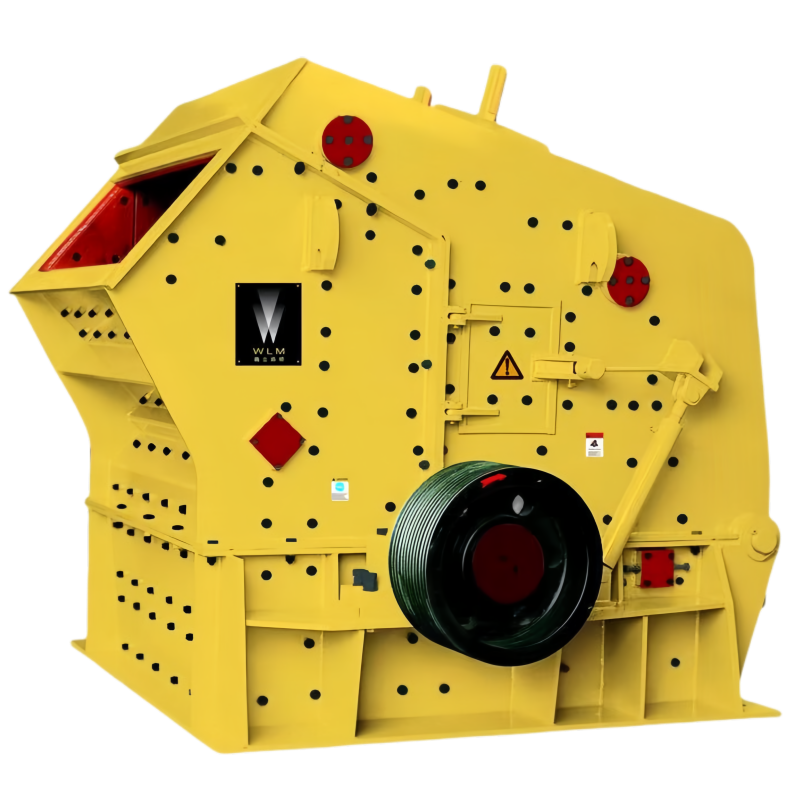

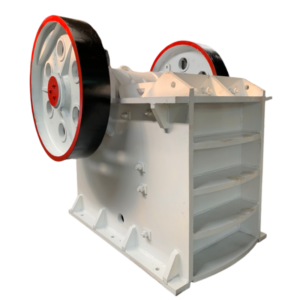

Impact Crusher

Maximum size:1500×2000

Maximum feed opening size:990×2030mm

Maximum feed size:700mm

Maximum production capacity:200-550mm

Maximum power:200*2(kw)

Maximum total weight:50t

Maximum dimensions:3960×3560×3330mm

- High quality material selection, casting superior performance

1. Strong main structure: The hammer plate is made of Q355 high-quality steel, the rotor is made of integral cast steel material, and the high manganese steel lining plate is used to protect the edge, creating a strong and durable core structure, providing a solid foundation for the stable operation of the equipment.

2. High impact plate hammer: The plate hammer cast with high chromium wear-resistant composite process has strong impact resistance, and always maintains stable performance in the process of high-speed impact materials to ensure efficient crushing.

3. Reliable bearing support: equipped with brand bearings, strong bearing capacity, can effectively cope with various stresses during equipment operation, to ensure smooth operation.

4. Strengthen wear-resistant parts: strictly implement the heat treatment process, greatly improve the strength of wear-resistant parts, extend the service life of key components, and reduce equipment maintenance costs. - Unique cavity shape, shape excellent grain shape

1. Innovative cavity design: The involute type crushing cavity design provides ideal space for material crushing and makes the finished particle shape more excellent.

2. High-quality grain type output: impact crushing method, so that the product particle size is more cube, this grain type in the market is better, to meet the strict requirements of a variety of construction and other industries on the shape of the material.

3. Efficient crushing principle: Based on the principle of “stone beating iron”, to achieve more crushing and less grinding, not only the crushing ratio is large, but also effectively reduce the powder yield, improve the quality of finished products and production efficiency. - Particle size control to ensure stable operation

1. Flexible particle size adjustment: The discharge particle size can be accurately and effectively controlled by adjusting the rotor speed, using the top bolt adjustment device to adjust the gap between the counter plate and the plate hammer, etc., to meet the diversified needs of different users for the finished material specifications.

2. Stable structural support: The bonding surface of the lower frame and bearing seat adopts the overall processing technology, and the bonding surface of the counter plate and the counter frame is firmly fixed to ensure that the equipment is stable and reliable during operation, reducing the risk of vibration and failure. - Reasonable structure to achieve higher production capacity

1. Optimize feeding and crushing: the crushing chamber is optimized, the feeding diameter is large, and the material passing volume is significantly increased. At the same time, the plate hammer and the rotor adopt rigid connection, with high-precision heavy-duty rotor, large moment of inertia, to provide powerful power for material crushing.

2. Efficient crushing space: The large crushing chamber design provides sufficient activity space for the material, so that it can make full use of the impact, greatly improve the crushing efficiency, and then improve the production capacity to meet the needs of large-scale production. - Safe and reliable, prevent congestion problems

1. Intelligent safety protection: equipped with self-weight safety device, with over-iron protection function, effectively avoid equipment failure caused by overload, reduce the loss of shutdown maintenance, and ensure safe and reliable operation of equipment.

2. Anti-clogging design: the feed chute and the counter plate can be configured with heating devices to prevent the material from clogging due to bonding. In addition, the counterattack breaks the bottom without grate, fundamentally avoiding the phenomenon of grate blockage when crushing wet materials, ensuring the smooth production process. - Hydraulic control, easy maintenance

1. Convenient clearance adjustment: The hydraulic adjustment system is used to easily adjust the distance between the counter frame and the plate hammer, which is simple and quick to operate and improves the production flexibility.

2. Efficient maintenance design: semi-automatic hydraulic open top device, greatly saving the time and labor cost of maintenance. The advanced tripartite frame structure makes the repair and maintenance of the plate hammer, counterattack plate, liner plate and other components only need to open the rear shell of the crusher to complete, further improving the maintenance efficiency of the equipment.

EQUIPMENT

The company mainly produces a complete set of equipment for coarse and fine crushing production lines of various hard materials such as coal gangue (solid waste) and mines, with high-fine crushers as the leading products.

SUPPORT

ZDMACHINERY's after-sales sales/service team is proud to provide 24/7/weekend service to support any emergency

RESOURCES

ZDMACHINERY's primary goal is to find just theright solution to help your businessgrow and stay profitable.

CONTACT

Contact us now to find out how wecan support all of your crushing,screening and conveying needs.